Descrption:

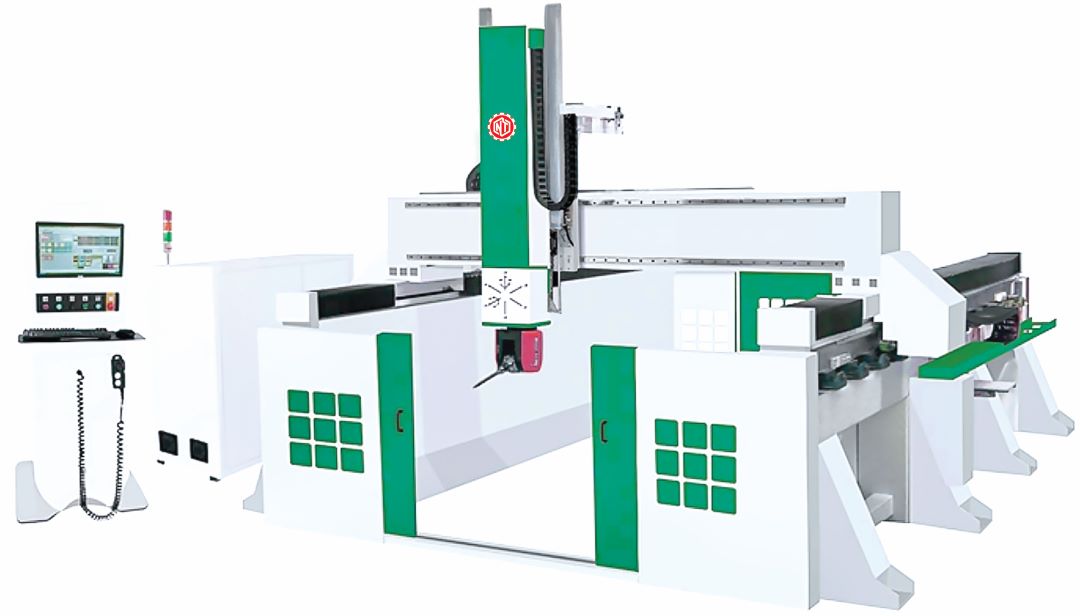

N10 high performance 5 axis cnc machining center is a high-tech, high-precision machining center specially used for processing complex curved surfaces. This machining center system is important for a country's aviation, aerospace, military, scientific research, and precision. Industries such as equipment and high-precision medical equipment have a decisive influence. At present, the five-axis linkage CNC machining center system is the only means to solve the processing of impellers, blades, marine propellers, heavy generator rotors, steam turbine rotors, large diesel crankshafts, and so on.

Feature:

The machine tool adopts an advanced gantry worktable mobile structure, which has the perfect milling technology characteristics of a high-speed milling machine. The mobile work table ensures that the machine tool has the best dynamic motion characteristics and the best driving rigidity.

The worktable moves smoothly in the axial direction. During processing, the five axes drive the tool to move and process around the workpiece to achieve five-axis five-linkage three-dimensional operation

The main components of the machine tool adopt a welded steel structure, and all main components have undergone strict two-time aging treatment, which eliminates the internal deformation stress of the components to the greatest extent, effectively improves the stability of the components, and avoids deformation, so that the machine tool has extremely high dynamic accuracy. , Static accuracy and stability.

Five-axis five-linkage, with RTCP function, suitable for large-scale three-dimensional surface processing and modeling.

Model NT 10 Working Size 1200 x 2800mm Structure of Table Multi-zone vacuum adsorption table Traveling Speed 65m/min Air Pressure > 6.5kgf/cm2 Type of Transmission XY Axis Rack, Z axis Screw Working Voltage AC380/3PH/50Hz Driving System Servo Drive Total Power 26KW Parameters of Spindle 9KW/24000RPM Total Weight 2800Kg Total Capacity 0~26m/min Boundary Dimension 4100x2200x2400mm