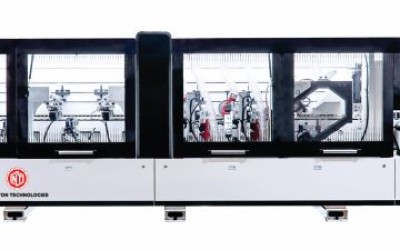

NT6.2 Double Process Six Sides Boring Automatic Cnc 6 Six Sides Drilling Machine For Wood Furniture:

The NT6.2 double-table six-sided drill adds a workbench to the single workstation and is mainly used for drilling and grooving after plate cutting.

When the plate is processed in one of the stations, the other station can simultaneously carry out loading and unloading work, and after processing in one of the stations. It can be processed directly in the other station, which improves the efficiency by about 30%.

Automatic tool changer spindle + row type tool magazine, Intelligent control system.

One-time import data, sweep code to complete processing, upper and lower spindles can process front and back symmetric slots at the same time.

Length of plate processing 250-2800mm, width of plate processing 55-1200mm, thickness of plate processing 50mm.

Specification NT6.2 Processing Length 250~2800mm Processing Width 55~1200mm Processing Thickness 50mm Maximum Machining Speed 80/130/15m/min Upper Drilling Package Structure 12 Vertical + 8 Horizontal Bottom Drilling Package Structure 9 Vertical Driving System Servo Drive Spindle Power 3.5KW/18000RPM Structure of Table Air bead countertop Working Voltage AC380/3PH/50Hz Working Air Pressure > 0.7Mpa Total Power 30KW Total Weight 8000KG Overall Size 6000x5100x2600mm