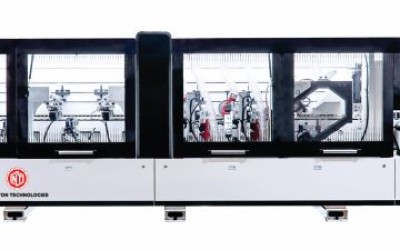

NT6.7 Atc Cnc Six Side Drilling Machine Cabinet Drilling and Milling Machining Center:

The NT6.7 drilling and milling composite machining center is mainly used for drilling and grooving operations in the production of panel furniture. It can not only meet the processing of mounting holes and slots for ordinary panel furniture two-in-one, three-in-one, Lock, Lamino and other connecting parts. , and can also realize grooving, milling and special-shaped cutting processing of plates.

Automatically identify plate processing information through scanning, automatically feed and process all holes and slots, and drill up and down the package. It has high processing accuracy, fast speed, and simple operation. It is suitable for customized furniture production and processing.

It can be connected to a fully automatic production line to realize an intelligent production line for cutting, drilling, and edge-sealing furniture manufacturing.

It has complete functions and is suitable for most processing techniques on the market: light trunking, straightening machine, sky and ground hinge, two-in-one connector, Lock connector, Lamino.

Good compatibility with computer operation: supports CAD drawing, CAM import, and can directly import open data formats such as DXF, MPR/XML, etc., with simple operation.

Model NT6.7 Processing Length 250~2800mm Processing Width 55~1200mm Processing Thickness 50mm Maximum Machining Speed 80/130/15m/min Upper Drilling Package Structure 12 Vertical + 8 Horizontal Bottom Drilling Package Structure 9 Vertical Driving System Servo Drive Spindle Power 3.5KW/18000RPM Structure of Table Air bead countertop Working Voltage AC380/3PH/50Hz Working Air Pressure >0.7Mpa Total Power 30KW Total Weight 8000KG Overall Size 6000x5100x2600mm